Cross-Docking explained simply: its meaning, definition and practical examples

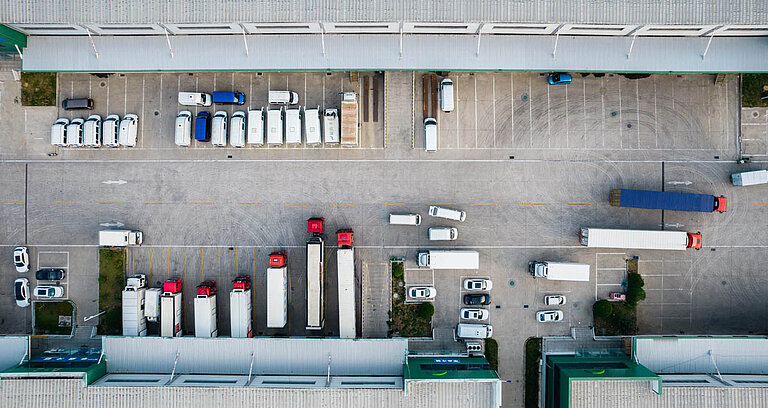

Cross-Docking is a logistics process in which goods are moved directly from the receiving area to the shipping area without being stored in a warehouse in between. The products are immediately transported further, saving time and reducing storage costs.

In this article, we delve into the meaning of Cross-Docking, explaining how it works in detail, the advantages it offers, the challenges it can present, and the industries where it is effectively applied. Let’s get started!

- What is Cross-Docking? Simply Explained!

- The Three Types or Levels of Cross-Docking

- Manufacturer to Retailer (Direct Shipment)

- Distribution & Consolidation (Consolidation Cross-Docking)

- Transport-Oriented (Transport Cross-Docking)

- The Key Advantages of Cross-Docking — With Examples

- How and Where is Cross-Docking Used? 10 Examples!

- The Challenges of Cross-Docking

What is Cross-Docking? Simply Explained!

Cross-Docking is a method in logistics where goods arriving at a warehouse or transshipment point are directly forwarded without being stored temporarily. This means that the products remain at a central location only briefly before usually being dispatched to the end customer or retailer within a few hours.

- The goal of Cross-Docking is to minimise storage and make transportation more efficient.

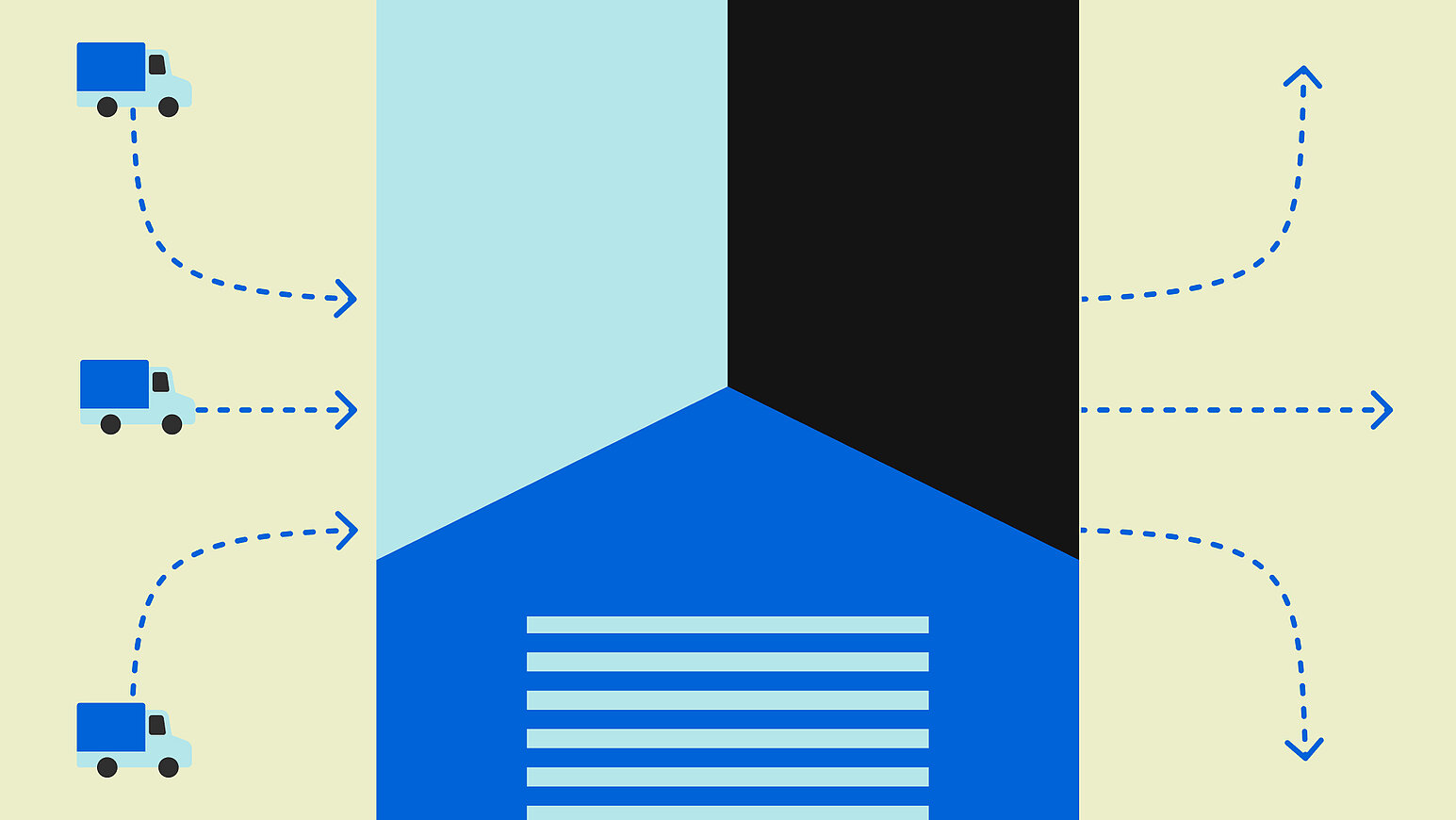

The process of Cross-Docking can be divided into two steps:

- Inbound: Goods are delivered to a distribution centre or transshipment point. These can be products from various suppliers or production facilities.

- Outbound: After arrival, the goods are not stored but immediately reloaded into new transport units (e.g., vehicles). These transport units then deliver the products directly to end customers, retailers, or other destinations.

By directly forwarding goods, storage is drastically reduced. Products stay only briefly at the transshipment point and are transported onwards as quickly as possible. This not only saves storage costs but also accelerates the entire delivery process, allowing goods to reach recipients more quickly.

The Three Types and Levels of Cross-Docking

The stages of Cross-Docking – single-stage, two-stage, and three-stage – describe how many steps goods go through before being forwarded to their destination. This refers to the complexity and the number of handling processes:

- Single-stage Cross-Docking: Goods are forwarded directly.

- Two-stage Cross-Docking: An additional step like sorting or consolidation is required.

- Three-stage Cross-Docking: A brief interim storage may occur before goods reach the end customer.

1. Single-Stage Cross-Docking – Manufacturer to Retailer (Direct Shipment)

In single-stage Cross-Docking, goods are transferred directly from the receiving dock to the outgoing dock without interim storage or repackaging. The items are loaded straight from the arriving truck or delivery vehicle onto the transport vehicle that will take them to their final destination.

- Typical Example: A manufacturer delivers finished products to a distribution center, where they are immediately loaded onto trucks and sent directly to stores or end customers.

- Advantage: Rapid processing since goods bypass additional handling steps.

- Application: Commonly used for products that are pre-packaged and ready for shipment, such as daily necessities or perishable goods.

2. Two-Stage Cross-Docking – Distribution & Consolidation (Consolidation Cross-Docking)

In two-stage Cross-Docking, there is an additional step between the receiving and shipping stages. Goods are consolidated or sorted at the distribution center before being reloaded for final transport. This often involves breaking down or combining shipments from multiple sources.

- Typical Example: Multiple shipments from various manufacturers arrive at a central hub. Goods are divided into smaller units or grouped into new shipments before being dispatched to various destinations.

- Advantage: Flexibility in assembling and forwarding shipments. Ideal for mixed consignments or just-in-time deliveries.

- Application: Frequently used by large retail chains distributing products from various suppliers to different store locations.

3. Three-Stage Cross-Docking – Transport-Oriented (Transport Cross-Docking)

Three-stage Cross-Docking is the most complex form and involves additional steps, including temporary storage or buffering before the goods are finally forwarded. While Cross-Docking aims to minimise storage, this stage incorporates short-term storage (e.g., overnight) to better coordinate the flow of goods and accommodate transport availability or delivery schedules.

- Typical Example: Goods arrive at a distribution center in the afternoon, are temporarily held in storage, and loaded onto transport vehicles the next morning for delivery to customers.

- Advantage: Greater flexibility in managing the flow of goods and transport schedules. Particularly useful when immediate onward transport is not feasible.

- Application: Used in complex logistics systems requiring just-in-time delivery or precise scheduling, such as in the automotive industry.

The Key Advantages of Cross-Docking — with Examples!

Cross-Docking offers numerous advantages, particularly in cost reduction, efficiency, and environmental sustainability. Here are the key benefits, illustrated with examples:

Reduction in Storage Costs

Since products are not stored but immediately transferred and transported, high warehousing costs are eliminated. Companies save significantly by avoiding storage space and operational expenses.

Example: A fashion retailer like Zara uses Cross-Docking to deliver new collections directly from production facilities to stores. With no need for prolonged storage, costs associated with seasonal inventory are avoided, and the company can quickly respond to trends.

Faster Delivery Times

By bypassing storage processes, products reach end customers more quickly, significantly improving customer satisfaction.

Example: Amazon employs Cross-Docking in its distribution centres to immediately forward products from suppliers. This enables services like same-day or next-day delivery, a central element of its business model that delights customers.

Efficient Supply Chain Utilisation

Cross-Docking allows companies to use resources like workforce, transportation, and storage capacity more efficiently. With reduced warehousing needs, vehicles and personnel can be deployed faster and more flexibly.

Example: In the automotive industry, Toyota uses Cross-Docking to deliver required parts just in time to the production line. Instead of storing large quantities, parts are delivered as needed, making production lines more efficient and reducing storage costs.

Improved Inventory Management

With fewer products in storage, inventory management becomes simpler. This minimises the risk of overstocking or obsolescence, especially for perishable or trend-driven products.

Example: Supermarkets like Walmart or Aldi use Cross-Docking to quickly move fresh food to stores. By minimising storage times, quality is maintained, and inventory is closely monitored to prevent waste.

Environmental Friendliness

Cross-Docking reduces transport routes and storage space requirements, lowering energy consumption and CO₂ emissions, thereby improving environmental sustainability.

Example: Unilever employs Cross-Docking to reduce CO₂ emissions through a leaner supply chain. Goods are delivered directly to distribution centres without detours or storage, reducing transport needs and energy usage.

Lower Handling Costs

Fewer handling processes (no unloading and reloading for storage) reduce labour costs and the risk of product damage caused by excessive handling.

Example: In the electronics sector, companies like Samsung use Cross-Docking to minimise handling of sensitive products such as televisions and smartphones. This reduces damage and eliminates costs associated with repackaging.

Flexibility for Unexpected Demand Fluctuations

Cross-Docking enables faster responses to changes in demand, as products move directly from suppliers to markets without delays caused by long storage periods.

Example: In the food industry, McDonald's uses Cross-Docking to ensure fresh ingredients like lettuce and meat arrive on time at their locations, even during high demand periods like large promotional campaigns.

Improved Product Quality

By minimising interim storage and associated risks like temperature and humidity fluctuations, product quality is preserved. This is crucial for perishable or temperature-sensitive goods.

Example: Pharmaceutical companies like Pfizer utilise Cross-Docking to quickly deliver medicines and vaccines to pharmacies and hospitals. Cross-Docking ensures necessary cold chains are maintained while avoiding delays.

Enhanced Collaboration Between Suppliers and Retailers

Cross-Docking requires close collaboration between suppliers, distribution centres, and end customers, fostering better communication and partnerships throughout the supply chain. This leads to optimised planning and improved teamwork.

Example: Nike employs Cross-Docking to coordinate deliveries with suppliers and retailers. This streamlined process ensures new products quickly reach store shelves, enhancing collaboration and efficiency across the supply chain.

Cost Reduction Through Consolidation of Shipments

Cross-Docking allows shipments from various manufacturers or suppliers to be consolidated at a central point before being forwarded to destinations. This reduces the number of transports and helps companies lower freight costs.

Example: FedEx and UPS consolidate shipments from various customers at regional distribution centres to maximise vehicle capacity and reduce transportation costs.

Where is Cross-Docking used?

10 examples and areas of application:

Cross-Docking is utilised across various industries, especially where rapid forwarding of goods is essential. Here are some key industries where Cross-Docking is successfully implemented, with examples:

1. Retail:

In the retail sector, particularly with large chains like Walmart or Amazon, Cross-Docking is used to quickly move products to stores or directly to customers. Retailers leverage this method to reduce storage costs and efficiently manage inventory at sales locations. This ensures they can respond swiftly to demand and keep shelves well-stocked.

Example: Amazon uses Cross-Docking to ship ordered products from various suppliers directly to customers without storing them in a warehouse. This enables faster delivery times.

2. Food Industry:

In the food industry, Cross-Docking is particularly beneficial as many products are perishable and must reach customers quickly. Fresh items like fruits, vegetables, dairy, and meat need to be processed and forwarded swiftly to maintain quality.

Example: A supermarket chain like Aldi employs Cross-Docking to deliver fresh produce such as fruits and vegetables daily from suppliers directly to stores without long storage times. This helps preserve the freshness of the products.

3. Automotive Industry:

In the automotive industry, Cross-Docking is often used in Just-in-Time (JIT) deliveries. Auto parts and components are delivered directly from suppliers to production lines without being stored in large quantities. This not only reduces storage costs but also ensures a smooth manufacturing process.

Example: An automobile manufacturer like Toyota uses Cross-Docking to integrate spare parts or components into the production line exactly when needed. This avoids unnecessary inventory.

4. Healthcare:

In the healthcare sector, particularly in hospitals and pharmacies, it is crucial that medicines and medical equipment are delivered quickly and reliably. Cross-Docking helps prevent shortages of essential medicines and ensures that needed products are always available.

Example: A hospital might use Cross-Docking to receive daily medical supplies directly from suppliers and immediately distribute them to wards or departments without prior storage. This ensures timely availability of necessary items.

5. Fashion Industry:

In the fashion industry, speed is crucial, especially for seasonal items or trends that need to be available in stores quickly. Cross-Docking ensures that new collections are delivered directly from the manufacturer to stores or distribution centres without delays caused by storage.

Example: A fashion company like Zara uses Cross-Docking to move new collections directly from production sites to stores. This enables them to respond rapidly to current fashion trends and sell products promptly.

6. Electronics Industry:

In the electronics industry, where expensive and delicate devices are often transported, Cross-Docking simplifies and accelerates inventory management. Electronics are frequently sourced from various suppliers and must be swiftly delivered to stores or directly to customers.

Example: Apple uses Cross-Docking to transport new iPhones and iPads directly from manufacturers to global distribution centres or retailers without prolonged storage.

7. Construction and Craft Industries:

In the construction sector and for craft projects, materials and tools often need to be delivered just in time to worksites. Cross-Docking ensures that required construction materials are delivered directly from suppliers to the site, eliminating the need for on-site storage.

Example: A construction company might use Cross-Docking to deliver building materials like cement or steel directly to the worksite precisely when they are needed.

8. E-Commerce and Shipping Logistics:

In e-commerce, fast delivery times and efficient supply chains are critical for success. Companies like UPS, FedEx, and DHL rely on Cross-Docking to quickly redirect packages and shipments without storing them in distribution centres for long periods. This reduces shipping times and enhances customer satisfaction.

Example: DHL uses Cross-Docking in their distribution centres to transfer shipments directly from aircraft to delivery vehicles heading to their destinations, significantly speeding up delivery times.

9. Pharmaceutical Industry:

The pharmaceutical industry also greatly benefits from Cross-Docking, as medicines and medical products are often time- or temperature-sensitive. These items must be forwarded quickly without intermediate storage to maintain their effectiveness.

Example: A pharmaceutical company might use Cross-Docking to transport medications directly from production facilities to pharmacies or hospitals without intermediate warehousing.

10. Consumer Goods Industry:

In the consumer goods industry, where fast-moving items like hygiene products or household goods are in constant demand, Cross-Docking efficiently manages replenishment. Companies must ensure that goods reach store shelves promptly.

Example: A manufacturer of household cleaning products might use Cross-Docking to deliver items directly from the factory to supermarkets and drugstores, ensuring inventory levels in stores are always up to date.

The Challenges of Cross-Docking

There are several challenges that companies must overcome to fully realise the benefits of Cross-Docking:

Increased Coordination

Cross-Docking requires precise synchronisation between suppliers, transport providers, and customers. Each participant in the supply chain must know exactly when and in what quantity products will arrive and be forwarded. Even minor communication issues or delays can disrupt the entire process and lead to inefficiencies.

Example: In the food industry, poor coordination between suppliers and the distribution centre can result in perishable goods arriving late, compromising freshness or leading to waste.

Dependence on Delivery Timeliness

For Cross-Docking to work efficiently, deliveries must arrive on time. Delays caused by traffic issues, weather conditions, or supplier errors can disrupt the entire process, leading to shortages or delayed deliveries.

Example: In the automotive industry, where just-in-time production is crucial, a delay in component deliveries can halt the entire production line, incurring significant costs.

Increased Investment in Technology

Successful Cross-Docking requires companies to invest in advanced technologies. These include warehouse management systems (WMS), barcode scanners, real-time tracking systems, and automated storage systems to ensure goods are identified, sorted, and forwarded immediately. Such technologies are often expensive and require additional staff training.

Example: Companies like Amazon invest heavily in automated systems and robotics to efficiently route goods through their distribution centres and ensure smooth Cross-Docking operations.

Specific Infrastructure Requirements

Cross-Docking requires specialised distribution centres with sufficient space and equipment to quickly unload and forward goods. In urban areas, where space is scarce and expensive, establishing such centres can be challenging and costly.

Example: In major cities like New York, finding suitable locations for Cross-Docking centres can be difficult due to high space requirements and real estate prices, complicating implementation.

Dependence on Reliable Suppliers and Transport Providers

Since Cross-Docking relies on the swift and seamless forwarding of goods, the reliability of suppliers and transport companies is crucial. Any failure or unreliability along the supply chain can significantly impact the entire process.

Example: In the fashion industry, if a logistics provider fails to deliver as planned, new collections may not reach stores on time, delaying sales launches and causing revenue losses.

Lack of Flexibility in Unforeseen Problems

Cross-Docking is designed for the fast and efficient forwarding of goods. However, in situations with unexpected problems—such as production delays, changes in customer requirements, or sudden demand fluctuations—the system can be inflexible. Without interim storage, there is little buffer capacity to absorb such changes.

Example: In the pharmaceutical industry, unexpected surges in demand for specific medications or production delays can make it difficult for Cross-Docking centres to meet needs promptly, as no stock reserves are available.

Quality Assurance and Product Protection

Ensuring product quality during rapid handling is another challenge for Cross-Docking. Products damaged during transport and handling can result in losses. This is particularly problematic for fragile goods like food or electronics, which are vulnerable to damage if frequently handled or improperly treated.

Example: In the electronics industry, frequent handling of sensitive devices such as smartphones can increase the risk of transportation damage, forcing companies to implement additional measures to protect products.

Cross-Docking is a proven and powerful logistics strategy that helps companies optimise their supply chain, reduce storage costs, and shorten delivery times. It offers numerous benefits, especially for businesses. We know this first-hand as long-standing fulfilment providers and logisticians.

- If you have further questions on the topic or are considering outsourcing your logistics, we are the right choice for you. Feel free to contact us, no strings attached.

Quellen

Pictures:

Unsplash

Quivo © 2025