The Future of Fulfillment: How AI and Robotics Are Optimizing E-Commerce Operations

E-commerce is expanding faster than ever, reshaping how consumers shop and how products move through the supply chain. As online retail accelerates, so do customer expectations. Today’s shoppers expect same- or next-day delivery, real-time tracking, seamless buying experiences, and sustainability — all at once.

Meeting these expectations requires more than traditional logistics. It calls for innovation at the very core of fulfillment. Among the most transformative forces driving this change are artificial intelligence (AI) and robotics — technologies that are revolutionizing how orders are processed, packed, and delivered worldwide.

In this article, we explore how AI and robotics are reshaping e-commerce fulfillment by transforming warehouses into intelligent hubs, enabling smarter inventory management, and optimizing last-mile delivery.

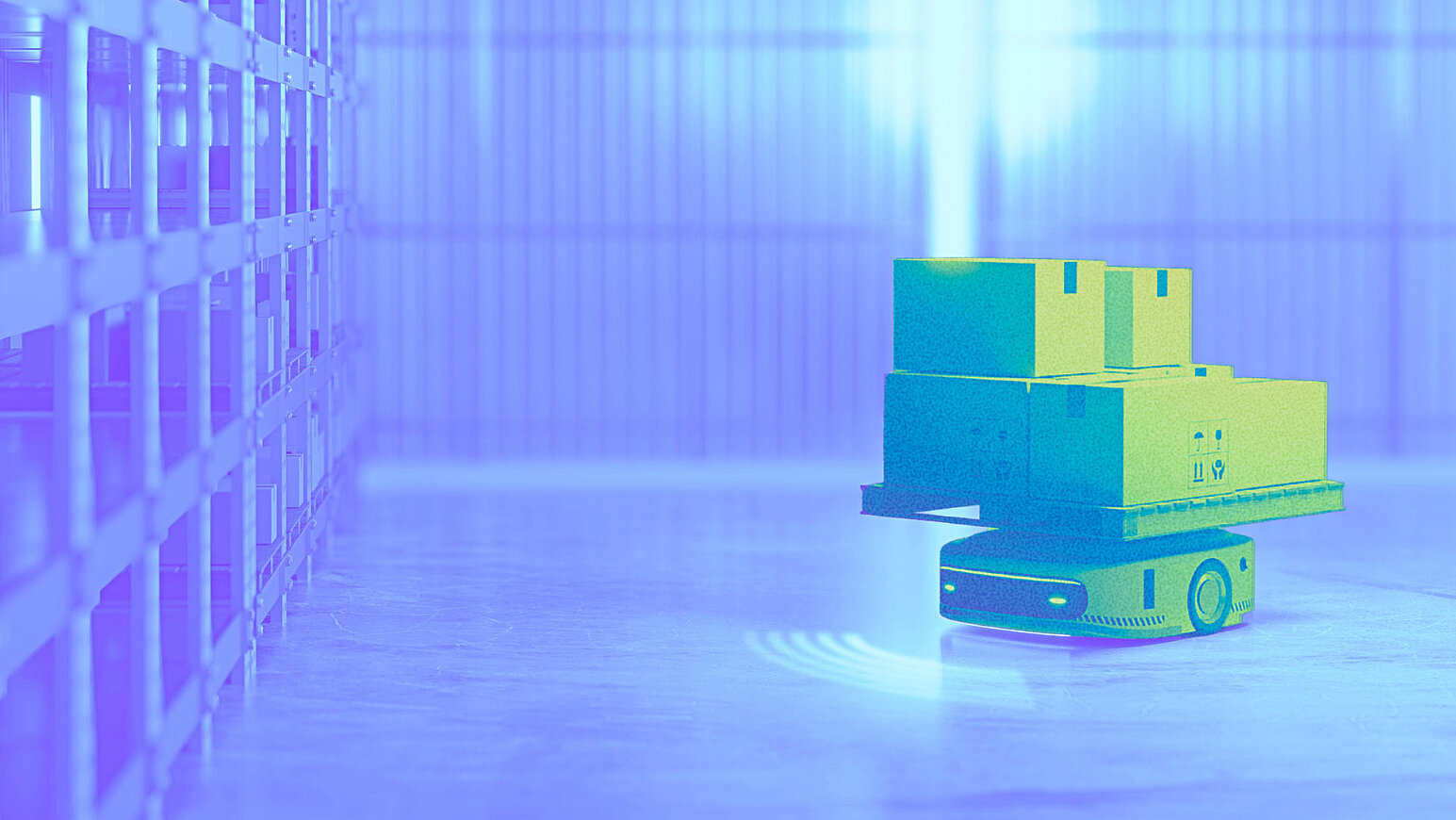

Warehouses Are Becoming Intelligent Hubs

Warehouses were once little more than places to store goods, but today they’re transforming into dynamic, intelligent fulfillment hubs where people and robots work together. Technologies like autonomous mobile robots (AMRs), robotic picking systems, and collaborative robotic arms -often called cobots — are now a regular part of many modern operations.

These tools take on repetitive, time-consuming tasks such as picking, packing, and sorting. By doing so, they reduce errors, speed up processes, and lower costs. For instance, companies like Amazon have seen cost savings of up to 25% after introducing robotics into their workflows, along with efficiency gains that continue to grow as order volumes increase.

Crucially, automation isn’t about replacing people- it’s about helping them do their jobs better. When robots handle the heavy lifting and repetitive work, human teams can focus on tasks that require judgment, problem-solving, and creativity, such as quality checks or improving workflows. The result is a workplace that’s not only more productive but also more resilient and engaging for the people who power it.

Artificial Intelligence as the Brain of Fulfillment

If robotics is the muscle of modern logistics, AI is the brain. Its ability to analyze massive volumes of data in real time is transforming how e-commerce businesses forecast demand, manage inventory, and execute deliveries.

- Smarter inventory planning: AI-driven forecasting models predict demand trends before they happen, ensuring products are in the right place at the right time. This reduces overstocking, prevents stockouts, and significantly improves customer satisfaction.

- Optimized warehouse operations: AI identifies the most efficient picking routes and automates task allocation, turning processes that once took hours into minutes while improving order accuracy.

- Enhanced last-mile delivery: AI continuously adapts delivery routes based on real-time factors such as traffic, weather, and order priority, helping packages arrive faster while reducing fuel consumption and emissions.

The result is a fulfillment process that’s faster, more accurate, more sustainable and ultimately more customer-centric.

Innovation Beyond the Warehouse

The impact of AI and robotics isn’t limited to what happens inside a fulfillment center — it’s transforming the entire logistics ecosystem from end to end. Emerging technologies are enabling smarter storage solutions, more agile distribution networks, and levels of automation once considered impossible.

For example, companies like Attabotics are reinventing inventory storage and retrieval with 3D robotic storage systems. Unlike traditional warehouses, which rely on long aisles and manual picking, Attabotics uses vertical, cube-like structures where robotic shuttles move products in three dimensions. This can boost storage density by up to 85%, accelerate order fulfillment, and reduce the physical footprint of facilities.

Meanwhile, companies such as Covariant are pushing the boundaries of AI-powered robotic arms that can identify, grasp, and sort thousands of different products with precision that rivals — and often surpasses — human capability. These robots continuously learn from every interaction, becoming more accurate and efficient over time. This adaptability is critical in e-commerce, where product types, packaging, and order complexity change constantly.

While not every business will directly adopt robotics, understanding these developments helps retailers and logistics partners make smarter strategic decisions. At Quivo, we closely follow these advancements to ensure our fulfillment solutions remain compatible with future technologies and evolving industry standards.

Safety, Sustainability, and Workforce Transformation

The benefits of AI and robotics go far beyond just speed and efficiency. One of the most meaningful advantages is a safer and healthier workplace. By taking over heavy lifting and repetitive tasks, automation reduces strain on workers, lowers the chance of injuries, and improves overall ergonomics. That means people can focus on work that’s less physically demanding and more rewarding.

Sustainability is another big win. Smarter routing, less packaging waste, and more efficient use of energy all help create greener and more eco-friendly logistics operations. And as more customers look to support brands that care about the planet, these steps become not just good practices but key business advantages.

As automation becomes more common, it’s also changing the kinds of jobs people do. Instead of spending all day on repetitive manual tasks, workers are moving into roles like robot monitoring, data analysis, and process improvement. This shift opens the door to new skills and career growth and helps create a workplace that’s more engaging, future-focused, and people-centered.

Challenges on the Road to Adoption

While the benefits of AI and robotics are clear, adopting these technologies comes with its own set of challenges. One of the biggest hurdles is cost. Advanced robotics systems and AI-powered software require a significant upfront investment, which can be especially tough for small and medium-sized businesses (SMEs) trying to stay competitive.

Another important factor is workforce readiness. As automation becomes more common, employees need to learn new skills — from data analysis and robot supervision to maintenance and troubleshooting. Without proper training and support, even the most advanced systems won’t deliver their full potential.

There’s also the need to find the right balance between automation and human work. Technology should support people, not replace them. Companies that manage this balance well are more likely to maintain a motivated workforce and a healthy workplace culture, while still enjoying the benefits of automation.

Tobias Lenhart COO of Quivo

"Technology can power logistics, but only people can transform it. Our task at Quivo is to combine human expertise with intelligent automation so that every process, every handover, and every shipment stands as proof of true operational excellence."

The Future of E-Commerce Fulfillment

The future of e-commerce will be shaped by the companies that embrace AI and robotics today. The formula is simple: AI + robotics = efficiency, sustainability, and long-term success. Businesses that invest in these technologies now will be the ones setting the pace in a market where speed, reliability, and environmental responsibility are no longer optional — they’re expected.

It’s also worth remembering that the next stage of online retail growth won’t be driven only by clever marketing or a wide product range. It will be built on strong, innovative logistics that create seamless customer experiences and support sustainable growth.

For brands looking to stay ahead, understanding these changes and preparing for them now is essential. And for fulfillment partners like Quivo, keeping pace with these trends means we can continue helping businesses navigate this new era of intelligent, automated, and customer-focused logistics.

Sources

Attabotics: Introduces Its Attabot 2022 Robot to Increase Warehouse Efficiency

Covariant AI Insights: Building Better, More Efficient Warehouses

Amazon news

Pictures: Quivo © 2025